PRODUCTS

PRODUCTS

HOT RECOMMENDATION

NEWS

CONTACT US

TEL

+86 0532 85778977

+86 189 5456 7296

info@luyumachinery.com

Exp. Office Add

Excellence Century Center, Shibei District, Qingdao, China

Factory. Add

Shahe industrial park, Laizhou City, Shandong Province, China

PARAMETERS

DETAILS

ADVANTAGES

1.Qualification

We have CE, ISO, EPA, OEM and other certificates.

2.Customisation

LUYU has more than 20 years of experience in manufacturing loaders. Our manufacturing techniques are perfectly suited to the private needs of our customers, completing a personalised and customised service.

3.After-sales

Online after-sales service. 24-hour handling.

4.Engine

A Yunnei engine is used as standard. The power is 90KW/123HP. according to the user's demand, we can also upgrade to Cummins, Kubota and other famous brands.

5.Buckets

Reinforced buckets for loaders automatic levelling throughout.Adopting large national standard 30 shovel teeth alloy steel shovel teeth, the strength and durability of the shovel teeth are enhanced several times.

6.Cabs

Comfort cab, can also be upgraded to a deluxe cab. Features such as the automatic suspension seat help you work with ease.

Luyu machinery adopts high quality materials and advanced manufacturing technology. Combine best practices in construction machinery manufacturing to ensure that every loader meets quality standards. LY946 2.5ton small wheel loader is a very practical wheel loader, through the quick change device can achieve a multi-purpose machine, can play a key role in various fields.

The quick-change device allows the LY946 2.5ton small wheel loader to quickly replace different types of accessory tools, such as buckets, forks, steel forceps, etc. This allows operators to quickly switch tools and adapt to different work needs, thereby increasing work efficiency and productivity. Traditionally, replacement units have required tools and additional labor to complete. The quick change device can complete the replacement of tools in a few minutes, saving tedious manual operation and additional labor costs, saving valuable time. The LY946 small wheel loader quick change device has been specially engineered and tested to ensure that it is robust and reliable, and provides good safety during use. Compared to traditional manual replacement devices, quick-change devices reduce the time and risk of the operator's contact with the tool, reducing the potential for injury and accident. The quick-change device enables the LY946 small wheel loader to adapt to different work scenarios and task requirements. By changing different tools, the LY946 small wheel loader can be used for loading, unloading, grasping, leveling and other operations to meet the requirements of different industries and applications. Thanks to the flexibility of the quick-change unit, the same loader can accommodate more types of work, reducing the need to purchase and maintain multiple dedicated units. This can reduce the cost of equipment and improve the efficiency of capital utilization.

FAQ

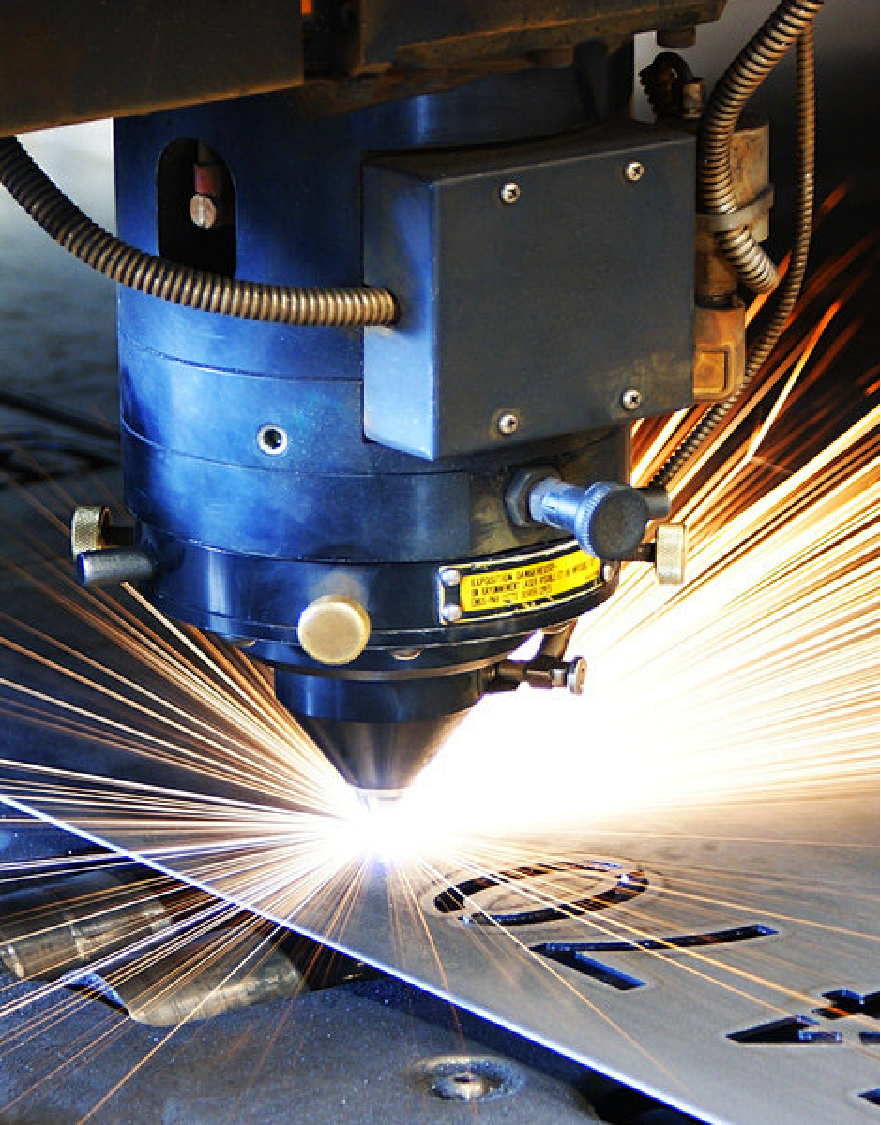

Q:How about the precision of the equipment process of LUYU wheel loader?

A:Luyu use laser cutting, robot welding and other processes. Ensure the precision of each wheel loader part and the stability and reliability of the equipment.

Q:What certifications has the loader achieved?

A:The luyu equipment has passed CE certification and ISO certification. At the same time we have been qualified for global export, we have EPA, EAC, etc.

Q:How to Maintain?

A:In daily use, the LY946 mini wheel loader equipment also needs regular maintenance to ensure its performance and life. The first is cleaning, after use, clean the equipment in time to remove the soil, residue or other debris attached to the surface. Use water and a brush to clean the tool and make sure it is completely dry to prevent rust. Also regularly check the cutting edge, teeth, claws and other parts of the wear and structural integrity. If excessive wear or damage is found, it should be repaired or replaced in time to ensure the normal operation and safe use of the tool. According to the manufacturer's recommendations, the lubrication points of the accessory tools are regularly lubricated, using appropriate lubricants to ensure that the lubrication points are sufficiently lubricated to reduce friction and wear. Periodically check the fastening bolts and connection points of accessory tools to ensure that they are secure and reliable. If it is found loose or worn, it should be tightened or replaced in time. If the equipment is not used for a long time, it should be stored in a dry and clean place to avoid exposure to bad weather conditions, and for parts that are easy to rust, you can consider using anti-rust agents for protection. The 946 small wheel loader should be regularly serviced and maintained according to the maintenance manual provided by the manufacturer. Including cleaning, lubrication, inspection and adjustment.

Inquiry

Our manager will contact you within 30 minutes of working hours.

Send Your Inquiry