PRODUCTS

PRODUCTS

HOT RECOMMENDATION

NEWS

CONTACT US

TEL

+86 0532 85778977

+86 189 5456 7296

info@luyumachinery.com

Exp. Office Add

Excellence Century Center, Shibei District, Qingdao, China

Factory. Add

Shahe industrial park, Laizhou City, Shandong Province, China

PARAMETERS

DETAILS

ADVANTAGES

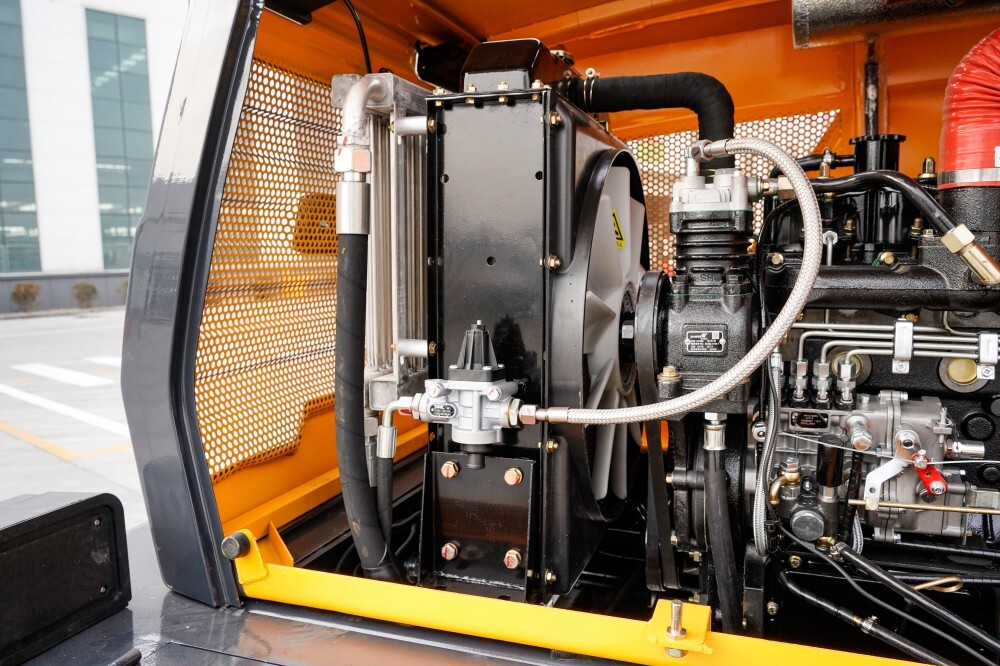

The overall size of the LY938 mini wheel loader is 5975*2000*3000 mm, and the engine is Yunnei brand. We have several engine brands to choose from and can replace the right engine for you according to your local emissions regulations. It should be noted that the price of different models of engines is different.

Loader maintenance should start from every detail, many operators in the loader maintenance, the first will think of the hydraulic system, engine and other major parts of the maintenance, but the loader bucket maintenance is also very critical, regular maintenance can extend its service life, and ensure its normal operation, the following are some of the daily use of maintenance recommendations.

1. Clean the bucket: After use, the bucket of the LY938 mini wheel loader should be cleaned in time to remove the soil attached to the surface. Residue or other debris. Use water and a brush to clean the bucket and make sure it is completely dry to prevent rust.

Check the bucket regularly: Check the bucket regularly for wear and structural integrity. Pay attention to observe whether the cutting edge, side wall and bottom of the bucket have cracks, wear or deformation. If problems are found, repair or replace them in time.

3. Lubricating bucket: Key parts of the bucket, such as hinged points, connecting rods and sliding parts, should be lubricated regularly. Use appropriate lubricants and lubricate as recommended by the manufacturer to reduce friction and wear.

4. Check the bucket connection point: Check the fastening bolts and pins of the LY938 mini wheel loader bucket connection point to ensure that they are secure and reliable. If it is found to be loose or worn, tighten or replace it in time.

5. Avoid overload use: Avoid overload use of the bucket to prevent damage or deformation, and reasonably control the loaded weight according to the specifications of the LY938 small wheel loader and the manufacturer's recommendations.

6. Regularly check the welding points: check the welding points of the bucket to ensure that the weld is firm. If the weld is found loose or cracked, it should be repaired or re-welded.

7. Regular maintenance and maintenance: Complete the maintenance manual provided by the manufacturer and carry out regular maintenance and maintenance. Includes changing hydraulic oil. Clean and replace filters, check and adjust hydraulic systems, etc.

8. Storage and protection: If the 2 ton mini wheel loader or bucket is not used for a long time, it should be stored in a dry and clean place to avoid exposure to bad weather conditions. For buckets, you can consider using anti-rust agents for protection.

The above suggestions are just some general maintenance methods, if you encounter some problems that cannot be solved, you can seek the help of some experienced operators. Of course, you can also consult the professional team of Lu Yu Machinery, we will answer all the questions about wheel loaders and other construction machinery for you.

FAQ

A:Each process of the automated assembly line is supervised by a quality inspector, and three detailed test runs will be conducted according to the standardized test list after the assembly is completed. All test drivers have at least 6 years of LUYU experience.All testers have more than 6 years of LUYU experience to ensure superior product quality.

Inquiry

Our manager will contact you within 30 minutes of working hours.

Send Your Inquiry