NEWS

Why choose LUYU loader?

LUYU hot-selling explosiveLY958 loaders are arranged together, driving out of the green and digitalized loading machinery manufacturing base. They departed to a mining area in Australia, opening a new chapter of the internationalization journey in the New Year.

Structural layout optimization

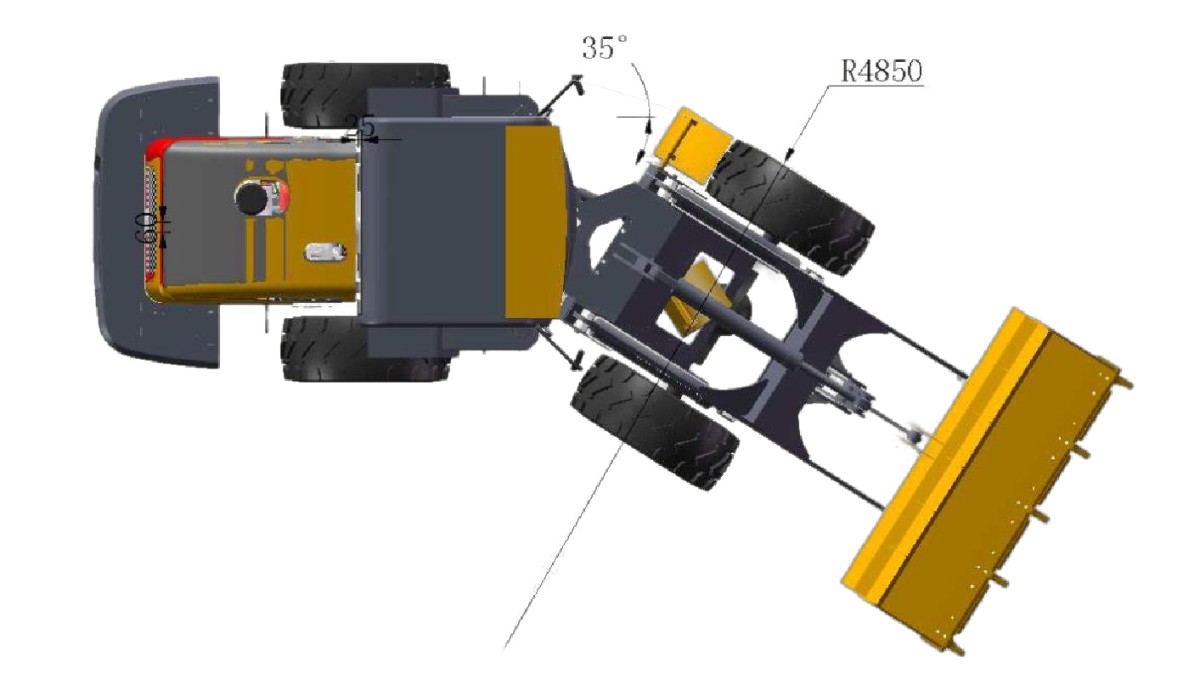

Optimization of the loader layout according to engineering mechanics. The whole vehicle is articulated in the center position. The center of gravity of the whole vehicle is shifted back, and the center of gravity can still fall on the front axle when the maximum load is applied, thus the stability is enhanced. The center of gravity is shifted back, the load is bigger, more compact, more flexible and more stable in operation.Good passability

The LUYU loader has a maximum turning angle of 35° and a turning radius of only 4.85 meters. With a turning radius of only 4.85 meters, the Luyu loader is agile and more suitable for operations on narrow sites.

Strengthening the bucket

Standard engineering bucket design with manganese steel plate for the main body.It is more wear-resistant and the bucket structure is strengthened. Adopting large national standard 30 shovel Alloy steel shovel teeth, shovel teeth strength and durability increased by several times.

Add supporting structures at the four corners of the bucket for structural reinforcement to improve its structural rigidity and load-bearing capacity.The structure is strengthened to improve its structural rigidity and load-bearing capacity.

The specially designed U-shaped hopper has a larger capacity and is less prone to spillage.It is also less prone to spillage.

Big arm lifting and lowering without dead angle

According to engineering mechanics principles, the width and curvature of the arms are designed accordingly for each model to achieve a smoother and lighter lifting effect.The bucket does not need to be leveled and can be raised and lowered at any angle.

Box-type rocker arm

To minimize the risk of the arm twisting and breaking, we not only use a thicker steel plate, but also a box structure. This makes the structure more stable, thus increasing the strength and durability of the arm.

High quality oil cylinder

Cylinder piston rod is modulated with 3 or more wires of hard chrome plating on the surface, which is 3 times higher than the common piston with 1 wire of chrome plating. The piston and guide sleeve are made of ductile cast iron. Imported polytetrafluoroethylene high quality oil seals are used. After welding, the cylinder barrel is straightened and refined to prevent the cylinder barrel from deformation due to welding, which will cause internal leakage and loss of power.

Share to :

Tag :

Inquiry

Our manager will contact you within 30 minutes of working hours.

Related products

| Recommended News

KB3.0 Spider Crawler Crane Operation Manual2025-04-161The KB3.0 spider crawler crane is designed with a crawler traveling mechanism and hydraulic system for lifting, tensioning and winding devices. The crane adopts advanced design methods such as UG 3D modeling, CAE component limit analysis and computer aided design to ensure flexibility, reliability and ease of operation.

KB3.0 Spider Crawler Crane Operation Manual2025-04-161The KB3.0 spider crawler crane is designed with a crawler traveling mechanism and hydraulic system for lifting, tensioning and winding devices. The crane adopts advanced design methods such as UG 3D modeling, CAE component limit analysis and computer aided design to ensure flexibility, reliability and ease of operation. What About China Luyu Mini Wheel Loader?2025-04-151Luyu Machinery has a wide range of product lines in the fields of wheel loaders, mini excavators, wheel excavators, off-road forklifts and various attachments. Our company continues to expand its production scale and improve its production capacity.

What About China Luyu Mini Wheel Loader?2025-04-151Luyu Machinery has a wide range of product lines in the fields of wheel loaders, mini excavators, wheel excavators, off-road forklifts and various attachments. Our company continues to expand its production scale and improve its production capacity. What Is An Air Prefilter For A Wheel Loader?2025-04-151The air prefilter (air filter) of the loader is an important part installed in the engine air intake system, mainly used to filter the air entering the engine, preventing dust, sand and other impurities from entering the engine, so as to protect the normal operation of the engine and prolong its service life.

What Is An Air Prefilter For A Wheel Loader?2025-04-151The air prefilter (air filter) of the loader is an important part installed in the engine air intake system, mainly used to filter the air entering the engine, preventing dust, sand and other impurities from entering the engine, so as to protect the normal operation of the engine and prolong its service life. Top 5 Reasons Why Mini China Excavators are Revolutionizing Construction Projects2025-04-141China's mini excavators are reshaping the global construction industry with five major advantages. This article analyzes its technological innovation and market competitiveness to help you make accurate purchasing decisions!

Top 5 Reasons Why Mini China Excavators are Revolutionizing Construction Projects2025-04-141China's mini excavators are reshaping the global construction industry with five major advantages. This article analyzes its technological innovation and market competitiveness to help you make accurate purchasing decisions!

Send Your Inquiry