NEWS

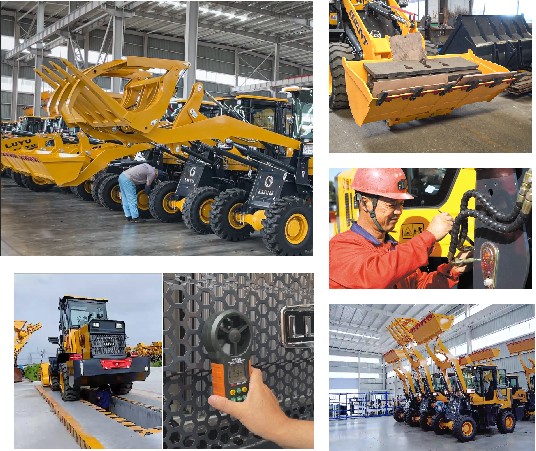

Each process of the automatic production line is monitored by a quality inspector, and after the assembly is completed, three meticulous test runs will be carried out according to the standardized test list. All the test drivers have more than 6 years of LUYU working experience to ensure excellent product quality. The test mainly contains the following major aspects:

1. Appearance check: check for scratches, dents, paint loss, etc.

2. Starting and sound check: start the engine, listen to whether the sound is normal, and observe whether the water temperature, oil pressure, voltage and other indicators are normal, etc.

3. Steering wheel and braking performance test: whether the steering wheel is sensitive, whether there is any stagnation phenomenon. Test whether the brake system is sensitive, whether the braking distance meets the requirements, and the reliability and stability of the brake in the ramp test.

4. Power and drivability test: accelerate to all levels of speed, whether there are abnormal noise or stall phenomenon. At the same time, test the driving performance, including straight line driving, turning radius, driving stability and so on.

5. Hydraulic system test: Observe whether the hydraulic pump has oil leakage, whether the hydraulic device works normally, and check the pressure and oil level of the hydraulic system.

6. Load test: According to the use environment and working conditions of the loader, determine the test objectives and requirements, and carry out the load spectrum test. By applying different types and intensities of loads to the loader and recording the load data output from the load sensors, in order to assess the load carrying capacity and performance of the loader.

The complete configuration report of the whole machine is retained for later traceability and analysis.

Share to :

Tag :

Inquiry

Our manager will contact you within 30 minutes of working hours.

Related products

LY10 1 ton mini excavator

LY10 1 ton mini excavatorEngine type KOOP 192F Rated power 7.6KW/10.5HP Operating weight 1000kg Bucket capacity 0.03 m³  LY10 PRO 1 ton mini excavator

LY10 PRO 1 ton mini excavatorEngine BRIGGS&STRATTON Rated power 10KW/13.5HP Operating weight 1000kg Bucket capacity 0.03m³  LZ20 2 ton mini excavator

LZ20 2 ton mini excavatorEngine Changchai390 Rated power 20Kw/29HP Operating weight 2000kg Bucket capacity 0.05m³

| Recommended News

KB3.0 Spider Crawler Crane Operation Manual2025-04-161The KB3.0 spider crawler crane is designed with a crawler traveling mechanism and hydraulic system for lifting, tensioning and winding devices. The crane adopts advanced design methods such as UG 3D modeling, CAE component limit analysis and computer aided design to ensure flexibility, reliability and ease of operation.

KB3.0 Spider Crawler Crane Operation Manual2025-04-161The KB3.0 spider crawler crane is designed with a crawler traveling mechanism and hydraulic system for lifting, tensioning and winding devices. The crane adopts advanced design methods such as UG 3D modeling, CAE component limit analysis and computer aided design to ensure flexibility, reliability and ease of operation. What About China Luyu Mini Wheel Loader?2025-04-151Luyu Machinery has a wide range of product lines in the fields of wheel loaders, mini excavators, wheel excavators, off-road forklifts and various attachments. Our company continues to expand its production scale and improve its production capacity.

What About China Luyu Mini Wheel Loader?2025-04-151Luyu Machinery has a wide range of product lines in the fields of wheel loaders, mini excavators, wheel excavators, off-road forklifts and various attachments. Our company continues to expand its production scale and improve its production capacity. What Is An Air Prefilter For A Wheel Loader?2025-04-151The air prefilter (air filter) of the loader is an important part installed in the engine air intake system, mainly used to filter the air entering the engine, preventing dust, sand and other impurities from entering the engine, so as to protect the normal operation of the engine and prolong its service life.

What Is An Air Prefilter For A Wheel Loader?2025-04-151The air prefilter (air filter) of the loader is an important part installed in the engine air intake system, mainly used to filter the air entering the engine, preventing dust, sand and other impurities from entering the engine, so as to protect the normal operation of the engine and prolong its service life. Top 5 Reasons Why Mini China Excavators are Revolutionizing Construction Projects2025-04-141China's mini excavators are reshaping the global construction industry with five major advantages. This article analyzes its technological innovation and market competitiveness to help you make accurate purchasing decisions!

Top 5 Reasons Why Mini China Excavators are Revolutionizing Construction Projects2025-04-141China's mini excavators are reshaping the global construction industry with five major advantages. This article analyzes its technological innovation and market competitiveness to help you make accurate purchasing decisions!

Send Your Inquiry